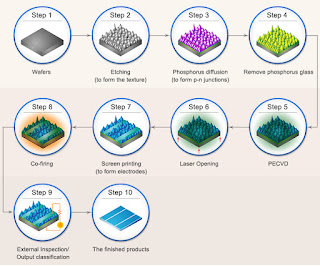

Solar panel menufectring process

Solar panels menufectring process step by step First off all the solar penal journey start to cell. This is tha basic material off it. Modual journey start step by step:- 1: Glass Lodar 2: EVA Cutting mashin 3: Stringar 4: Bussing 5: Layup 6: Back sheet cutting mashin 7: Pree Visual 8: Pree EL 9: Rework 10: Leminetion 11: Triming Mashin 12: Post Visual 13: post EL 14: Framing 15: JB Fixing 16: Soldring 17: Poting 18: Quring 19: Cleaning 20: High Pot 21: Sun Simulator 22: Final EL 23: Final Visual 24: SAP 25: Packing 26: Dispatch Finally our penel become ready to Sall. Every step of solar panels menufectring process discuss in below to grow up your knowledge very fast. It's helpful for you. Read and learn about more soral penal. 1:- Glass lodar Glass lodar is a simpal mashin. This is work on vacuum pressure. In this mashin 4 to 6 vacuum cup are available on their. ...