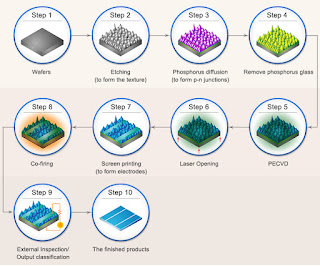

Solar Cell Production Process

1. Standard Solar Cell Production Process

2. PERC Solar Cell Production Process

| Wafer Clean: |

| Using acid or alkali liquid to do saw damage removal. |

| Texturing: |

| Using acid or alkali liquid to texture. |

| Diffusion: |

| High temperature vacuum tube process with (POCl3 ) gas to define positive/ negative electric junctions. |

| Wet Edge Isolation: |

| Using Acid liquid to remove SiO2 layer from wafer surface and doing isolation on wafer edge. |

| Chemical Vapor Deposition: |

| Chemical vapor deposition by tube to build anti-reflection layer (SiNx) on wafer surface. |

| Laser Opening: |

| The formation of a high-quality local back-surface-field (LBSF) using by laser opening. |

| Screen Printing: |

| Screen printing the electrode pattern on both side with metal component paste. |

| Co-Firing: |

| Using high temperature heater to make cross-link between electrode and junction for electric current output. |

| Efficiency Test : |

| Classify cells by surface visual inspection with AOI and electricity with IV-tester. |

Comments

Post a Comment