Photovoltaic Panel Construction

The Complete Module

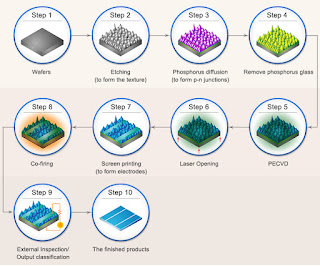

On the How Panels Work page, what we are really describing is one Solar Cell. Each cell consists of two wafers of "doped" silicon (p-type and n-type), in contact to form a junction, with each wafer having an electricla connection.

Typically, each cell, whilst very thin, measures approximately 100mm across. One of these cells may be capable of producing up to 0.7 volt, with maximum power being produced at a voltage of around 0.4 V.

Several of these Solar Cells will be wired together as a module and protected from the weather to create what we call a panel, or sometimes refered to as a module.

A 24 volt (nominal) panel may have 72 Solar Cells within it, wired in series, giving its maximum power at a voltage of approximately:

0.4 x 72 = 28.8 volts.

Typically, each cell, whilst very thin, measures approximately 100mm across. One of these cells may be capable of producing up to 0.7 volt, with maximum power being produced at a voltage of around 0.4 V.

Several of these Solar Cells will be wired together as a module and protected from the weather to create what we call a panel, or sometimes refered to as a module.

A 24 volt (nominal) panel may have 72 Solar Cells within it, wired in series, giving its maximum power at a voltage of approximately:

0.4 x 72 = 28.8 volts.

These cells will sit on a tough backing plate, while the grid of electrical connections lies above and below the cells of the cells. Electrical connecting strips will go from the bottom of one cell to the top of the next, connecting cells in series.

Over this will be a non reflective layer (Silicon is naturally reflective), to increase light absorption.

Finally on top will be a layer of tough glass, and the whole structure is usually within an aluminium frame, sealed against the weather.

On the photograph to the right, you can clearly see thin silver conducting strips printed to the upper surface of the cell. Also the main conducting strips which connect to the printed strips, going from the top of one cell to the bottom of the next.

Thin Film Modules

Using amorphous silicon that can be sprayed onto a surface, or the newer materials that are being developed, has the potential to greatly reduce material and production costs. It also gives a wide option of materials that can be used in the construction, including flexible and light weight materials.

The wide choice of construction materials on which thin film pv cells can be printed opens up new areas in which they can be used, including within window glass, on roofing tiles, and even tent material, for solar powered camping.

As these types of panels tend to be less efficient than those using silicon wafer cells, some companies are developing Multi-junction thin film technology.

The wide choice of construction materials on which thin film pv cells can be printed opens up new areas in which they can be used, including within window glass, on roofing tiles, and even tent material, for solar powered camping.

As these types of panels tend to be less efficient than those using silicon wafer cells, some companies are developing Multi-junction thin film technology.

Comments

Post a Comment